- Home

- Products

- CNC Lathe

- Flat Bed CNC Lathe

- CHC Series Flat Bed CNC Lathe

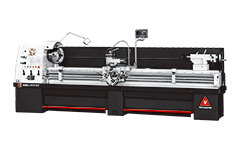

CHC Series Flat Bed CNC Lathe

| MODEL | CHC-2240 | CHC-2260 | CHC-2280 | CHC-22120 | ||

|---|---|---|---|---|---|---|

| Capacity | No. of control axis | 2 AXIS | ||||

| Swing over bed | Ø550 mm (21.653") | |||||

| Distance between centers | 870 mm (34.25") | 1370 mm (53.93") | 1870 mm (73.62") | 2870 mm (113.0") | ||

| Max. working length | 4 way tool post | 680 mm (26.77") | 1180 mm (46.45") | 1680 mm (66.14") | 2680 mm (105.5") | |

| Hyd. P8 turret | 590 mm (23.22") | 1090 mm (42.91") | 1590 mm (62.60") | 2590 mm (102.0") | ||

| Hyd. VDI disc | 550 mm (21.65") | 1050 mm (41.33") | 1550 mm (61.02") | 2550 mm (100.4") | ||

| Max. working diameter | Ø325 mm (12.8") | |||||

| Width of bed | 345 mm (13.58") | |||||

| Headstock and Main Spindle | Spindle nose, internal taper | ASA A2-8 , Ø97mm Taper 1/20 | ||||

| Spindle bore / Bar capacity | Ø91mm (3.582") / Ø78mm (3.07") | |||||

| Range of spindle speed No. of spindle speed |

35~3500 R.P.M Infinitely variable |

|||||

| Cross Slide (X-axis) and Carriage (Z-axis) | Cross slide travel ( X-axis ) STD. | 300 mm (11.8") | ||||

| Longitudinal travel ( Z-axis ) STD. | 780 mm (30.7") | 1280 mm (50.4") | 1780 mm (70.1") | 2780 mm (109.4") | ||

| AC servo motor ( X-axis ) | 1.8 kW 11N.m ~ FANUC s12 / 3000is | |||||

| AC servo motor ( Z-axis ) | 2.5 kW 20N.m ~ FANUC s22 / 2000is | |||||

| Dia. of ball screw ( X-axis) | Ø25 mm (0.98") P5 C5 | |||||

| Dia. of ball screw ( Z-axis ) | Ø50 mm (1.97") P10 C5 | Ø63 mm (2.48") P10 C5 | ||||

| Rapid traverse speed ( X-axis ) | 7.5 m/min (295 ipm) | |||||

| Rapid traverse speed ( Z-axis ) | 10 m/min (394 ipm) | |||||

| Turret | Tool station | STD. Manual 4 way tool post ☐25 mm | OPT. Hyd. VDI.V8 ☐25 mm Ø40 mm (1.575") or Hydraulic P8 ☐25 mm Ø32 mm (1.26") |

|||

| Size of external turning tool | ||||||

| Boring bar diameter | ||||||

| Tailstock | Quill diameter | Ø85 mm (3.346") | ||||

| Quill travel | 178 mm (7") | |||||

| Taper of center | MT.No.5 | |||||

| Motor | Main spindle (continuous rated) | AC 9 kw (12HP) Wide range heavy duty Fanuc AC spindle motor | ||||

| Main spindle (30 min. rated) | AC 11kw (15HP) MODEL siIp18/6000 | |||||

| Hydraulic oil pump | STD. 0.75 kW (1 HP) OPT. 1.5 kW (2 HP) | |||||

| Coolant pump | 1 / 6 HP | |||||

| Tank Capacity | Hydraulic tank | STD. 25 Litre (5.5 gal.) OPT. 40 Litre (8.8 gal.) | ||||

| Coolant tank | 60 L (13.2 gal.) | 120 L (26.4 gal.) | 180 L (39.6 gal.) | 240 L (52.8 gal.) | ||

| Measurements | Weight ( Net / Gross ) Approx. | 4,050 kgs / 4,450 kgs | 4,400 kgs / 4,900 kgs | 4,800 kgs / 5,400 kgs | 5,300 kgs / 6,000 kgs | |

| Packing sizes | Length | 3200 mm (126") | 3700 mm (145.7") | 4200 mm (165.4") | 5200 mm (204.7") | |

| Width x Height | Width 2300 mm (90.6") x Height 2230 mm (87.8") | |||||

Standard Accessories:

- CNC Controller: FANUC 0i Mate-TC

- Hydraulic chuck 10" with rotary cylinder

- Rotating center MT.5

- Level pads (2240/2260/2280)............8pcs

Level pads (22120)..........................10pcs - Tool set and box

- Machine light

- Operation manual & parts list

Optional Accessories:

- Hyd. VDI 40 disc V8 w/o tool holder

- Hydraulic P8 turret with

boring bar holder Ø32mm...... 2 sets

facing tool holder ☐25mm..... 2 sets - Boring socket Ø8 x Ø32~Ø25 x Ø32

- Drilling socket MT.1 x Ø32, MT.2 x Ø32, MT.3 x Ø32

- Steady rest w / ball bearing

- High pressure coolant pump 3bar 750W

- Quick change tool post

- Manual quill feed 1/1 & 1/4

- Hydraulic tailstock quill

- Chip conveyor & chip buck cart

Enlarged Saddles and Fully Supported Cross Slide (X-axis)

- Bed ways and cross slide are hardened and ground to min HS70.

- Turcite "B" coating between the bed and carriage.

8-Station Hydraulic Turret (Optional)

Direct-driven Main Spindle Motor

- The spindle is supported by a single cylinder bearing housing equipped with SP level precision double row cylindrical roller bearings angular contact thrust bearings and lubricated with HI-class grease. The front spindle is designed with a labyrinthian collar and protector cover to prevent the entering of coolant or chips.

- Encased in a well-ribbed headstock for maximum heat dissipation. Prevents any thermal distortion after long periods of turning thereby ensuring accurate cutting.