- Home

- Products

- CNC Lathe

- Flat Bed CNC Lathe

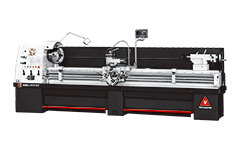

- CHL Series Flat Bed CNC Lathe

CHL Series Flat Bed CNC Lathe

| MODEL | CHL-2140 | CHL-2160 | CHL-2180 | CHL-21120 | ||

|---|---|---|---|---|---|---|

| Capacity | No. of control axis | 2 AXIS | ||||

| Swing over bed | Ø533 mm (20.98") | |||||

| STD. D1-6 distance between centers | 845 mm (33.27") | 1345 mm (52.95") | 1845 mm (72.64") | 2845 mm (112.0") | ||

| STD. D1-8 max. working length | 4 way tool post | 620 mm (24.41") | 1120 mm (44.09") | 1620 mm (63.78") | 2620 mm (103.1") | |

| Hyd. P8 turret | 530 mm (20.87") | 1030 mm (40.55") | 1530 mm (60.24") | 2530 mm (99.61") | ||

| Elec. VDI turret | 490 mm (19.29") | 990 mm (38.98") | 1490 mm (58.66") | 2490 mm (98.03") | ||

| Max. working dia. | Ø305 mm (12") | |||||

| Width of bed | 345 mm (13.58") | |||||

| Headstock and Main Spindle | Spindle nose, internal taper | STD. D1-8 OPT. A2-8, Ø85 mm Taper 1/19.18 | ||||

| Spindle center sleeve | Ø85 mm Taper 1/19.18 x MT.No.5 | |||||

| Spindle bore | Ø80 mm (3.149") | |||||

| Spindle speed: Gear steps / Range |

M code automatic 4 steps / | |||||

| M41 | 20~60 | R.P.M | ||||

| M42 | 61~200 | R.P.M | ||||

| M43 | 201~670 | R.P.M | ||||

| M44 | 671~2000 | R.P.M | ||||

| Infinitely variable | ||||||

| Cross Slide (X-axis) and Carriage (Z-axis) | Cross slide travel ( X-axis ) STD. | 300 mm (11.8") | ||||

| Longitudinal travel ( Z-axis ) STD. | 720 mm (28.3") | 1220 mm (48.0") | 1720 mm (67.7") | 2720 mm (107.1") | ||

| AC servo motor ( X-axis ) | 1.3 kW 8.34 N.m | |||||

| AC servo motor ( Z-axis ) | 2.9 kw 18.6 N.m | |||||

| Dia. of ball screw ( X-axis) | Ø25 mm (0.98") P5 C5 | |||||

| Dia. of ball screw ( Z-axis ) | Ø50 mm (1.97") P10 C5 | Ø63 mm (2.48") P10 C5 | ||||

| Rapid traverse speed ( X-axis ) | 7.5 m/min (295 ipm) | |||||

| Rapid traverse speed ( Z-axis ) | 10 m/min (394 ipm) | |||||

| Turret | Tool station | STD. Manual 4 way tool post ☐25 mm | OPT. Hyd. VDI.V8 ☐25 mm Ø40 mm (1.575") or Hydraulic P8 ☐25 mm Ø32 mm (1.26") |

|||

| Size of external turning tool | ||||||

| Boring bar diameter | ||||||

| Tailstock | Quill diameter | Ø85 mm (3.346") | ||||

| Quill travel | 178 mm (7") | |||||

| Taper of center | MT.No.5 | |||||

| Motor | Main spindle | Inverter Motor AC 11 kW (15 HP), Inverter (15 HP) | ||||

| Hydraulic oil pump | OPT. 0.75 kW (1HP) OPT. 1.5 kW (2HP) | |||||

| Forced lubrication for headstock | 1/4 HP | |||||

| Automatic gear shift | 60 W | |||||

| Coolant pump | 1/6 HP | |||||

| Tank Capacity | Hydraulic tank | OPT. 25 Liter (5.5 gal.) OPT. 40 Liter (8.8 gal.) | ||||

| Coolant tank | 60 L (13.2 gal.) | 120 L (26.4 gal.) | 180 L (39.6 gal.) | 240 L (52.8 gal.) | ||

| Measurements | Weight ( Net / Gross ) Approx. | 4,050 kgs/ 4,450 kgs | 4,400 kgs/ 4,900 kgs | 4,800 kgs/ 5,400 kgs | 5,300 kgs/ 6,000 kgs | |

| Packing sizes | Length | 3700 mm (145.7") | 3700 mm (145.7") | 4200 mm (165.4") | 5200 mm (204.7") | |

| Width x Height | Width 2300 mm (90.6") x Height 2240 mm (88.2") | |||||

Standard Accessories:

- CNC Controller

- Rotating center MT.5

- Level pads ( 2140/2160/2180 ) ....... 8pcs

Level pads ( 21120 ) ....... 10pcs - Tool set and box

- Machine light

- Operation manual and parts list

Optional Accessories:

- 3-Jaw scroll 12" chuck

- 4-Jaw independent 14" chuck

- Hyd. VDI 40 disc V8 w/o tool holder

- Hydraulic P8 turret with

boring bar holder Ø32 mm.....2 sets

facing tool holder ☐25 mm.....2 sets - Boring socket Ø8 x Ø32~Ø25 x Ø32

- Drilling socket MT.1 x Ø32, MT.2 x Ø32, MT.3 x Ø32

- Steady rest w / ball bearing

- High pressure coolant pump 3bar 750W

- Quick change tool post

- Manual quill feed 1/1 & 1/4

- Hydraulic tailstock quill

- Chip conveyor & chip bucket cart

- Hydraulic hollow chuck 10" with rotary cylinder / bar capacity Ø68 for A2-8 spindle only

(Working length increased more 70mm)

Extra Rigid Solid Construction Bracket, for Ball Screw and Motor (Z-axis)

8-Station Hydraulic Turret (Optional)

Headstock

- Four gear range of spindle speeds driven by built-in AC motor. The operator can input the required spindle speed by M code, and the spindle will automatically reach the required speed.

- The headstock has forced oil lubrication, with lubricant pumped from a large tank to maintain constant temperature.

- The 3 ultra-precision bearing spindle support maintains stability in heavy cuts. O80 mm (D3.15") spindle bore through diameter shafts.

- ASA A2-8 short taper for power chuck or Cam-Lock D1-8 spindle nose for quick and accurate chuck mounting.