- Home

- Products

- CNC Lathe

- Flat Bed CNC Lathe

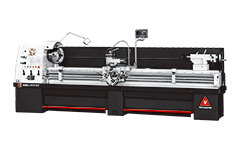

- CSR Series Flat Bed Horizontal CNC Lathe

CSR Series Flat Bed Horizontal CNC Lathe

| MODEL | CSR-1840 | CSR-1860 | |||

|---|---|---|---|---|---|

| Capacity | No. of control axis | 2 AXIS | |||

| Swing over bed | Ø460 mm (18.11") | ||||

| STD. D1-6 distance between centers | 900 mm (35.43") | 1400 mm (55.11") | |||

| STD. D1-6Max. working length | 4 way tool post | 750 mm (29.52" | 1250 mm (49.21") | ||

| Hyd. P8 turret | 600 mm (23.62") | 1100 mm (43.3") | |||

| Max. working dia. | 4 way tool post | 260 mm (10.2") | |||

| Hyd. P8 turret | 250 mm (9.84") | ||||

| Width of bed | 305 mm (12") | ||||

| Headstock and Main Spindle | Spindle nose, internal taper | A2-6, Ø69 mm Taper 1/20 | |||

| Spindle bore | Ø65 mm (2.56") | ||||

| Spindle speed | Gear steps | Pneumatic change 2 steps / Infinitely variable | L 270~830 R.P.M. | ||

| Range | H 831~2500 R.P.M. | ||||

| Cross Slide (X-axis) and Carriage (Z-axis) | Cross slide travel ( X-axis ) STD. | 230 mm (9.05") | |||

| Longitudinal travel ( Z-axis ) STD. | 850 mm (33.46") | 1350 mm (53.15") | |||

| AC servo motor ( X-axis ) | 7.0N.m ~ FANUC s8 / 3000is | ||||

| AC servo motor ( Z-axis ) | 7.0N.m ~ FANUC s 8 / 3000is | ||||

| Dia. of ball screw ( X-axis) | Ø20 mm (1.57") P10 C5 | ||||

| Dia. of ball screw ( Z-axis ) | Ø40 mm (0.787") P5 C5 | ||||

| Rapid traverse speed ( X-axis ) | 7.5 m/min (295 ipm) | ||||

| Rapid traverse speed ( Z-axis ) | 10 m/min (394 ipm) | ||||

| Turret | Tool station | STD. Manual 4 way tool post ☐25 mm | OPT. Electric H4 ☐20 mm or Hydraulic P8 ☐20 mm Ø20 mm (0.787") |

||

| Size of external turning tool | |||||

| Boring bar diameter | |||||

| Tailstock | Quill diameter | Ø68 mm (2.677") | |||

| Quill travel | 153 mm (6") | ||||

| Taper of center | MT. No.4 | ||||

| Motor | Main spindle | continuous rated | STD. AC7.5 kW (11 HP) | ||

| 30min. rated | STD. AC11 kW (15 HP) | ||||

| Hydraulic oil pump | OPT. 0.75kw (1HP) OPT. 1.5kw (2HP) | ||||

| Forced lubrication for headstock | 1/4 HP | ||||

| Coolant pump | 1 / 6 HP | ||||

| Tank Capacity | Hydraulic tank | STD. 25 Litre (5.5 gal.) OPT. 40 Litre (8.8 gal.) | |||

| Coolant tank | 60 L (13.2 gal.) | 85 L (19.7 gal.) | |||

| Measurements | Weight ( Net / Gross ) Approx. | 2,350 kgs / 2,850 kgs | 2,600 kgs / 3,100 kgs | ||

| Packing sizes | Length | 2860 mm (112.6") | 3360 mm (12.3") | ||

| Width x Height | Width 2115 mm (83.3") x Height 2340 mm (92.1") | ||||

Standard Accessories:

- CNC controller:FANUC 0i Mate - TC

- CNC Controller

- Rotating center MT.4

- Level pads - 6 pcs

- Tool set and box

- Machine light

- Operation manual & parts list

Optional Accessories:

- 3-Jaw scroll 8" chuck

- 4-Jaw independent 10" chuck

- Electric H4 turret

- Hydraulic P8 turret with

boring bar holder Ø20 mm........2 sets

boring bar holder Ø25 mm........1 set

O.D / facing tool holder........4 sets

I.D / facing tool holder........1 set - Boring socket Ø6 xØ20~Ø16 x Ø20

- Drilling socket MT.1 x Ø20

- Steady rest w / ball bearing

- High pressure coolant pump 3bar 750W

- Quick change tool post

- Hydraulic tailstock quill

- Chip conveyor & chip bucket cart

- Hydraulic hollow chuck 8" with rotary cylinder / bar capacity Ø52

Advanced User-Friendly CNC Control Interface

Well-Machined Parts